This product reflects the technological expertise within the ElringKlinger Group. Two more applications – suitable for the Iveco Cursor 11 and 13 engine series – are already under development and will soon complement the range.

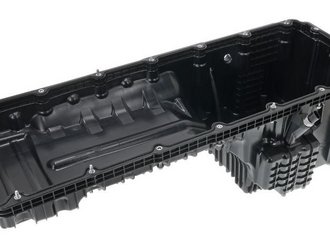

With this new product line, Elring is aiming to make plastic oil pans a firm fixture in its Aftermarket portfolio. The turnkey oil pan comes complete with gaskets and fastenings and offers a precise fit as well as being extremely durable and easy to install.

Lightweighting expertise at the highest level

Elring’s plastic oil pan for trucks was developed specifically for the extreme conditions faced in the commercial vehicle sector and is designed to withstand permanently high operating temperatures inside the engine compartment and extreme temperature fluctuations caused by cold starts. The precision workmanship ensures reliable sealing and reduces the number of individual components required, making installation much easier and enabling weight savings of up to 60 percent compared to conventional metal oil pans.

Lightweighting technology and its benefits

Lightweighting is one of the key technologies of the future in the mobility sector, and Elring is focusing on bespoke solutions that have already proven their worth in the field of original equipment manufacturing – delivering both commercial and environmental benefits. The use of thermoplastics enables a significant weight reduction compared to standard metal oil pans. This lower weight cuts fuel consumption and carbon emissions, making a significant contribution to cost-effectiveness and sustainability. Plastic also conducts less heat, improving thermal insulation and helping to make the engine more efficient. The highly flexible nature of the material enables shocks and vibrations to be cushioned more effectively without any cracking or deformation. Thermoplastics are also resistant to corrosion, making them particularly durable – a clear advantage over metal, which can rust when exposed to moisture or road salt. They also generally allow noise levels to be reduced by around 2 dB, thus helping the vehicle to run more quietly.

Suitable for a wide range of vehicles

The new plastic oil pan suitable for the Mercedes-Benz OM 471 is compatible with many different models, as a result of which it can be used in a wide range of commercial vehicles and motorcoaches:

- Actros MP4 and MP5

- Antos

- Arocs

- Travego

Replacing the plastic oil pan correctly

The oil pan should always be replaced by a professional to keep it fully leak-tight and in perfect working order. Here is a brief overview of the most important steps:

- Preparation: Park the vehicle safely, allow the engine to cool down, and drain the oil.

- Removal: Take out the old oil pan and clean the sealing surfaces.

- Installation: Use the Dirko sealant supplied to fix the new oil pan in place and tighten the screws to the recommended torque.

- Filling: Top up the engine oil in accordance with the manufacturer’s specifications and check the oil level.

- Final steps: Start the engine, check leak-tightness, retighten the screws in accordance with the manufacturer’s specifications, and then dispose of the old parts in line with environmental regulations.

Read the online catalog

All the technical details and product information can be found in Elring’s online catalog or on TecDoc.

More information is available from:

ElringKlinger AG | Strategic Communications

Dr. Jens Winter

Phone: +49 7123 724-88335 | Email: jens.winter@elringklinger.com

About Elring

The Elring aftermarket brand offers everything in a single package: original equipment quality, functional reliability, and efficient, all-round service. This includes, for example, sales and technical training courses, service information, exploded-view drawings for trucks and vans, monthly newsletters with topics relating to engine sealing, online sealant advice, innovative installation videos, the Elring Academy, the training truck, and much more besides.

Original Elring products are highly regarded among dealers, mechanics, and their customers around the globe. In addition to cylinder head and specialty gaskets, this also includes rotary shaft seals and valve stem seals, sealing compounds, and threadlockers as well as cylinder head bolts and complete gasket sets for full and partial overhauls. Elring is also committed to the electrification of its aftermarket portfolio by adding new products to the range.

![[Translate to Englisch:] [Translate to Englisch:]](/CELUM/10008/14310/Neuaufnahme_rot.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/CELUM/10008/14310/ZKS_rot.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/CELUM/10008/14310/SORK_rot.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/CELUM/10008/14310/ZKDS_rot.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/CELUM/10008/14310/PLAT_rot.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/CELUM/10008/14310/ZKD_rot.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/CELUM/10008/14310/DIMA_rot.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/CELUM/10008/14310/COIL_rot.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/CELUM/10008/14310/Spezialdichtungen_rot.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/CELUM/10008/14310/DIRI_rot.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/CELUM/10008/14310/Sonderanfertigungen_rot.jpg)